Welcome to SkyZulpo - Aerospace Engineering and Aircraft Services.

SkyZulpo is an engineering services and consulting company dedicated to providing certification solutions to the aviation industry on a global scale. Our team has extensive experience on design, structural analysis, testing, and certification of structural repairs and modifications for Commercial, Executive and Military aircraft, including aircraft components.

As a company focused on the development of aeronautical engineering projects, we prioritize quality and punctuality, seeking to exceed the expectations of customers. Our highly skilled aerospace engineers are committed to solving complex problems and meeting tight deadlines throughout the design-to-certification process. We offer turnkey solutions compliant with FAR 23, FAR 25, FAR 27, and FAR 29 regulations.

On staff, we have ANAC Designated Engineering Representatives (DERs) that review and approve data for structural repairs and aircraft modifications. We also specialize in obtaining Supplemental Type Certifications (STCs) for our customers.

Our customers are airlines of all sizes, repair stations, aircraft lessors/sellers, MRO companies, aircraft operators and private groups. Additionally, we proudly serve the Brazilian Armed Forces and military police units.

25 years of experience approving over 10,000 aircraft repairs on various aircraft types including Embraer (120/145/170/190/E190-E2 and executive jets), Boeing (727, 737 and 757), Airbus A320 Family, Lockheed C-130 Hercules and Cessna Caravan.

Clients

Our capabilities also include support for:

- Unique Structural Challenges: Addressing aircraft damage beyond SRM limits, requiring innovative solutions.

- Material Approval: Expertise in approving alternative materials for structural repairs.

- Structural Modifications: We specialize in obtaining approvals for modifications, including the installation of Galleys, Bulkheads, Wardrobes, Overhead bins, and lavatories, as well as the installation of antennas and other equipment within the fuselage.

- Adaptive Approaches: Successfully obtaining approvals for deviations in process and material specifications, spanning Composites, Metallic, and non-metallic elements.

- Empowering Skills: Offering specialized training in SRM, Aircraft Structural Repair Design and Analysis, and Aircraft Structures Familiarization.

- Post-Incident Damage Assessment: Skillfully assessing damage after incidents for prompt decision-making.

- Quick Approvals: Speedy major repair approval for repetitive damage with previously approved data.

- Custom Repairs: Demonstrated success in approving repairs not covered by vendors and OEMs, focusing on interiors parts and composite fairings.

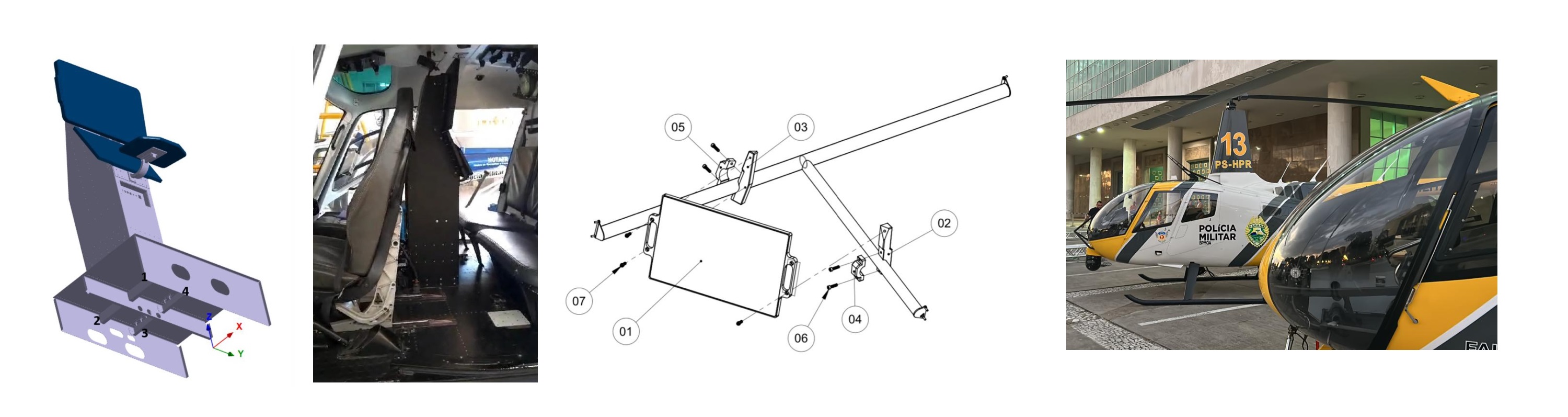

- STC Project Expertise: SkyZulpo demonstrates proficiency in Supplemental Type Certificate (STC) projects, exemplified by the successful completion of the first STC project (CST No: 2023S05-07) for the Robinson R66 Police helicopter. Our skilled engineering team, managing all certification aspects and structural analyses.

Discover how our tailored solutions and industry insights make us a trusted partner in the aviation sector.